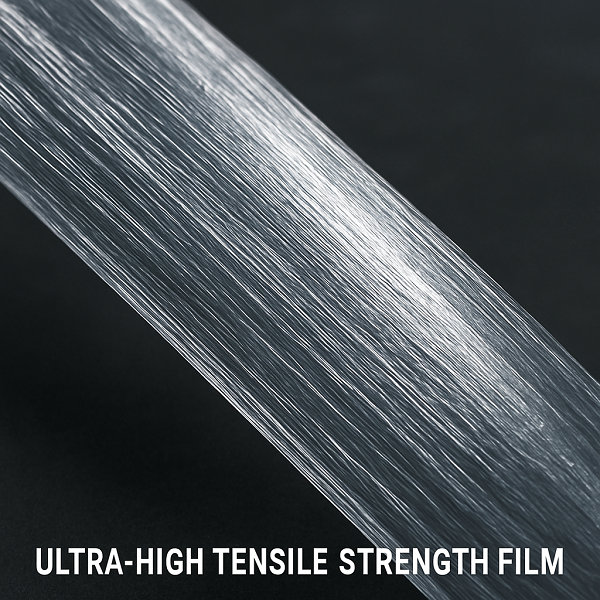

Ultra-High Tensile Strength Film has become a transformative innovation in the ever-evolving field of materials science. Known for their exceptional strength-to-weight ratio, thin profile, and durability, these advanced materials are pushing the boundaries of technology in everything from aerospace to consumer electronics. UHTSF is playing an increasingly important role as industries demand lighter, stronger, and more sustainable solutions.

What is Ultra-High Tensile Strength Film?

Ultra-High Tensile Strength Film refers to a class of films with tensile strengths that far exceed those of traditional polymers or composites. Typically made from materials such as ultra-high molecular weight polyethylene (UHMWPE), aramid fibers, or carbon nanomaterials, these films are able to withstand significant stresses without deforming or breaking.

Key properties include:

- Tensile strength over 1 GPa (gigapascal).

- Lightweight and flexible

- Excellent chemical and heat resistance

- Excellent fatigue resistance

Breakthrough applications

- Aerospace & Defense: UHTSF is being used to reinforce aircraft skins, deployable space structures, and ballistic armor. The material's high strength and low weight help improve fuel efficiency and enhance protection without sacrificing mobility.

- Flexible electronics: Next-generation displays and wearable devices are using UHTSF because of its mechanical strength and flexibility. It allows screens and circuits to bend, stretch, or fold without loss of functionality.

- Medical Devices: In healthcare, UHTSF is being used in surgical sutures, vascular grafts, and implantable devices. Its biocompatibility and high durability make it ideal for long-term use in the body.

- Building and civil engineering: Reinforced concrete structures and high-performance membranes are benefiting from UHTSF as a reinforcing agent. Its corrosion resistance and high tensile modulus help extend service life and reduce maintenance.

- Sustainability and Manufacturing: One of the most compelling aspects of Ultra-High Tensile Strength Film is its potential environmental benefits. By enabling lighter structures and more efficient systems, it helps save energy throughout the product's life cycle. Recent advances in green manufacturing technologies, such as solvent-free spinning or recyclable precursor materials, also make Ultra-High Tensile Strength Film more sustainable.

Future Outlook

The UHTSF market is expected to grow significantly over the next decade, driven by innovations in nanotechnology, additive manufacturing, and smart materials. Researchers are currently exploring self-healing films, bio-derived polymers, and multifunctional composites to further enhance performance.

With the growing demand for stronger, lighter, and more adaptable materials, UHTSF films are bound to be at the forefront of the next wave of engineering marvels.

More than just a high-performance material, Ultra-High Tensile Strength Film is a key enabler of innovation in key industries. As manufacturing methods mature and applications expand, UHTSF will undoubtedly shape the future of technology, infrastructure, and sustainability.