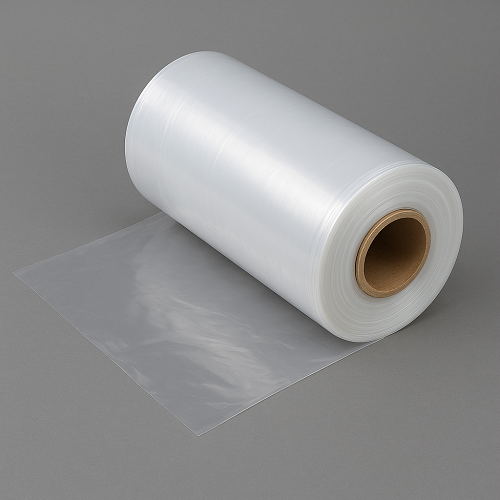

Our HDPE (High-Density Polyethylene) Film Roll is engineered to meet the diverse needs of industrial and commercial packaging. Designed for both protective and functional applications, it serves as an excellent solution for wrapping, covering, and sealing products across a wide range of sectors. The film’s high tensile strength and resistance to tears and punctures ensure that items are safely transported and stored. Whether used in agricultural covers, pallet wrapping, shrink films, or moisture-resistant packaging, our HDPE Film Roll delivers consistent performance, safeguarding products from dust, moisture, and external environmental factors while maintaining clarity and flexibility.

Product Features

The HDPE Film Roll is distinguished by its superior durability and lightweight structure, combining flexibility with exceptional mechanical strength. Its non-toxic and eco-friendly composition makes it suitable for applications requiring food-grade or chemical-resistant packaging. The film exhibits excellent resistance to UV radiation, chemical corrosion, and temperature variations, ensuring long-term reliability in both indoor and outdoor environments. Its smooth surface provides easy printing, labeling, or lamination, making it versatile for branding and informational purposes. Anti-slip and anti-static variants are also available to meet specific handling requirements.

Product Specifications

Our HDPE Film Rolls are available in a variety of thicknesses, widths, and lengths to cater to specific industrial needs. Standard thickness ranges from 20 to 200 microns, with widths varying from 0.5 meters to 2.5 meters, and roll lengths of 100 to 1,000 meters depending on the application. The film is manufactured to strict tolerances, ensuring uniformity in thickness, strength, and clarity across the roll. Custom colors, perforation options, and co-extrusion layers are available upon request, allowing clients to tailor the film for specialized packaging requirements.

Product Instructions

For optimal usage, HDPE Film Rolls should be stored in a cool, dry environment away from direct sunlight and heat sources to maintain its mechanical properties. When cutting or handling the film, ensure sharp tools are used to avoid uneven edges or tearing. For industrial wrapping or pallet applications, the film should be stretched appropriately to maximize its tensile strength without overstressing. In applications involving food or chemicals, ensure the film meets the relevant regulatory standards for contact safety. Cleaning and maintenance are minimal, typically requiring only a dry wipe to remove dust or debris before use.

Applicable Industries

HDPE Film Rolls are widely utilized across industries including food packaging, agriculture, pharmaceuticals, logistics, electronics, and construction. In agriculture, the film serves as a protective cover for crops, greenhouses, and silage, promoting yield preservation. In logistics and warehousing, it is used to wrap pallets and products for secure transportation. The pharmaceutical and electronics sectors benefit from its anti-static and chemical-resistant variants, while the construction industry uses it as a vapor barrier and moisture-resistant sheet. Its adaptability makes it a vital material in virtually any sector requiring strong, reliable, and versatile film solutions.

Customer Groups

Our HDPE Film Rolls cater to a broad customer base, including manufacturers, distributors, wholesalers, packaging companies, agricultural businesses, and industrial service providers. Small and medium enterprises looking for cost-effective, high-quality packaging solutions, as well as large-scale industries needing consistent bulk supply, find our products ideal. Additionally, environmentally-conscious clients seeking recyclable and sustainable film options are well served by our range, as we emphasize high performance without compromising environmental responsibility.