Whatsapp:+86-13484110552

Email:tanglc@zjzhongda.com

Whatsapp:+86-13484110552

Email:tanglc@zjzhongda.com

Zhongcheng Strength Film is produced using salivation composite technology. Using high-density polyethylene (HDPE) as the main raw material, it is produced through processes such as blow molding, unidirectional stretching, rotary cutting, and extrusion salivation composite. It is a high-strength composite film with high mechanical properties and isotropic equilibrium.

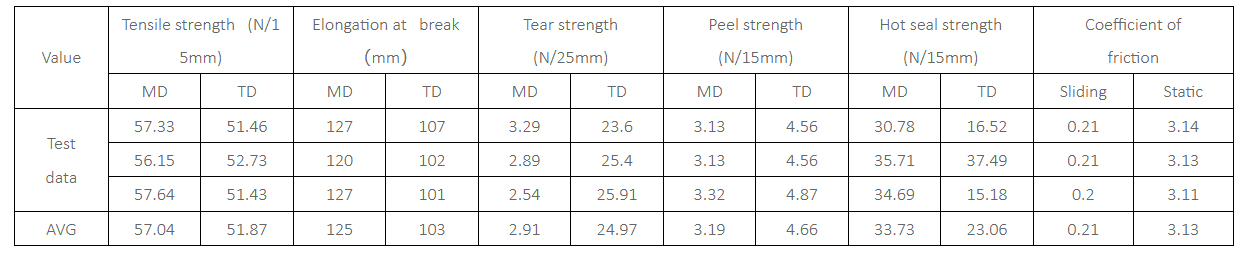

1. High tensile strength, good tear resistance, high tear strength of nail rod.

2. The production and use process is environmentally friendly, without any glue and solvent residues;

3. High adhesion fastness, no delamination, and no impact of environmental climate;

4. Good thermal stability and dimensional stability, not easy to be warped or curled by heat.

5. The surface shall be smooth without vertical cross creases;

6. Excellent UV resistance and aging resistance.

The typical application field of Zhongcheng Strength Film is the waterproofing film industry, which can be used as a core layer support material to produce double-sided asphalt waterproofing film, or as a surface layer to produce single-sided asphalt waterproofing film. The waterproof roll material produced with Zhongcheng strength film has the advantages of good laying performance, good flatness, and not easy to curl up.

Our Waterproofing Film for Construction provides reliable moisture protection to ensure long-lasting durability for a variety of construction projects. Waterproofing Film For Construction is easy to apply and adheres seamlessly to surfaces, creating a strong waterproof barrier that prevents water infiltration and structural damage. Whether used in basements, roofs, or foundations, our Waterproofing Film for Construction enhances the integrity of any construction site. It is weather, corrosion, and aging resistant, and provides superior performance in harsh conditions. Protect your investment and meet high industry standards by choosing our construction waterproofing membranes. It's the ideal solution for builders seeking efficiency, safety, and long-term value.

Waterproofing is one of the most critical yet often overlooked elements of building durability. Among the many waterproofing technologies and materials available, Waterproofing Film for Construction has emerged as a highly effective and versatile solution. From foundations to roofs, the use of Waterproofing Film for Construction in buildings significantly improves the structural integrity and longevity of buildings.

Waterproofing membranes are thin, flexible films designed to prevent water from penetrating building materials. These membranes are typically made from materials such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), or advanced polymer blends, and form a seamless barrier that effectively resists moisture and prevents water infiltration caused by rain, groundwater, or wet conditions.

We always adhere to customer needs as the core, and are committed to providing high-performance, highly customized product solutions for various industries.

Name: Richard

Mob/WhatsApp: +86-13484110552

Tel: +86-573-84186115

E-mail: tanglc@zjzhongda.com

Name: Carrie

Mob/WhatsApp: +86-18805818996

Tel: +86-573-84186115

E-mail: wujw@zjzhongda.com

Name: Altair

Mob/WhatsApp: +86-13484116086

Tel: +86-573-84186115

E-mail: zhuc@zjzhongda.com

Address: No. 1, Taishan Road, Huimin Street, Jiashan, Zhejiang ,China 314100

Website: Waterproofing Film For Construction

Our professional team will provide you with technical support and customized suggestions as soon as possible. No matter which industry you come from or the scale of your project, we are your trusted partner.

We attach great importance to your advice and consultation.If you have any questions about the products and services of Zhongcheng, please fill in the following form, and we will contact you as soon as possible.