House membrane waterproofing is a critical component of modern residential construction and renovation. It involves the application of specialized barrier materials—known as waterproofing membranes—to prevent water ingress into a building’s structure. Properly designed and installed membrane systems protect foundations, walls, roofs, and floors from moisture-related damage such as mold growth, concrete deterioration, corrosion of reinforcement, and reduced thermal performance.

Purpose and Importance of Waterproofing Membranes

Waterproofing membranes serve as a continuous, impermeable layer that blocks liquid water while often allowing limited vapor transmission (depending on membrane type).

Their primary objectives include:

- Structural protection: Preventing water-induced degradation of concrete, masonry, timber, and steel.

- Durability enhancement: Extending the lifespan of building components.

- Indoor environmental quality: Reducing mold, mildew, and dampness.

- Energy efficiency: Preserving insulation performance by keeping it dry.

- Compliance: Meeting building codes and standards related to moisture control.

Water intrusion can occur through hydrostatic pressure, capillary action, wind-driven rain, condensation, or groundwater seepage—membranes are engineered to address one or more of these mechanisms.

Types of Waterproofing Membranes

Waterproofing membranes can be broadly categorized based on material composition and application method.

Sheet Membranes

Sheet membranes are factory-manufactured rolls applied to surfaces with adhesives, heat welding, or mechanical fastening.

Common materials:

- Bituminous membranes (SBS or APP modified bitumen)

- PVC (polyvinyl chloride)

- TPO (thermoplastic polyolefin)

- EPDM (ethylene propylene diene monomer)

Advantages:

- Uniform thickness and controlled quality

- High tensile strength and puncture resistance

- Suitable for high-risk areas (basements, roofs)

Limitations:

- Complex detailing at corners and penetrations

- Seams are potential failure points

- Requires skilled installation

Liquid-Applied Membranes

Liquid membranes are applied by brush, roller, or spray and cure to form a seamless waterproof layer.

Common materials:

- Polyurethane

- Acrylic

- Cementitious coatings

- Polyurea

Advantages:

- Seamless application

- Excellent for complex geometries

- Easy detailing around penetrations

Limitations:

- Thickness control depends on applicator skill

- Curing time affected by temperature and humidity

- Some products have limited UV resistance

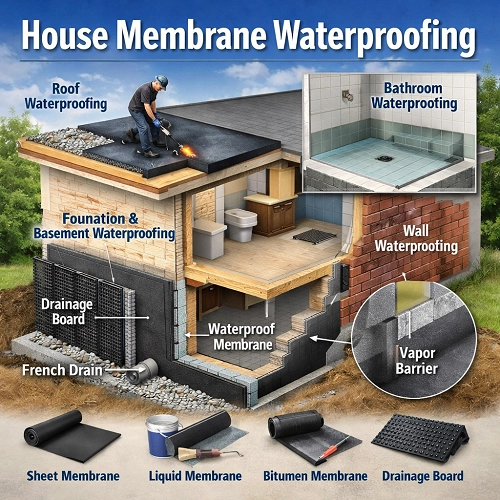

Key Areas of Application in Residential Buildings

Foundation and Basement Waterproofing

Foundations are subject to hydrostatic pressure from surrounding soil moisture and groundwater.

Typical systems include:

- External membrane waterproofing (positive-side)

- Internal waterproofing (negative-side) for retrofit situations

- Drainage boards and protection layers

- Perimeter drainage systems (e.g., French drains)

Design considerations:

- Soil type and permeability

- Water table level

- Foundation depth and construction material

Roof Waterproofing

Roofs are exposed to direct rainfall, UV radiation, thermal movement, and wind uplift.

Common residential roof membranes:

- Bituminous torch-on membranes

- Single-ply membranes (PVC, TPO, EPDM)

- Liquid-applied elastomeric coatings

Key technical aspects:

- UV stability

- Thermal expansion compatibility

- Drainage slope and ponding resistance

Wet Areas (Bathrooms, Kitchens, Balconies)

Internal wet areas require waterproofing beneath tiles or finishes to prevent water migration into structural elements.

Requirements:

- Flexible membranes to accommodate movement

- Compatibility with tile adhesives

- Upturns at walls and penetrations

Walls and Facades

Wall membranes manage rainwater penetration and vapor diffusion.

Types:

- Breathable (vapor-permeable) membranes

- Cavity wall membranes

- Air and water barriers combined

Material Properties and Performance Criteria

When selecting a waterproofing membrane, engineers and builders evaluate several technical properties:

- Water impermeability (hydrostatic pressure resistance)

- Elongation and flexibility

- Crack-bridging capability

- Adhesion to substrate

- Chemical resistance

- UV resistance

- Vapor permeability (µ-value or perm rating)

- Service life and aging behavior

Standards such as ASTM, EN, and ISO define test methods for these properties.

Installation and Detailing Considerations

Substrate Preparation

Proper substrate preparation is essential:

- Clean, dry, and free of contaminants

- Surface defects repaired

- Primers applied if required

Detailing and Penetrations

Critical failure points often include:

- Pipe penetrations

- Expansion joints

- Corners and transitions

- Terminations at walls or slabs

Preformed corners, reinforcement fabrics, and compatible sealants are commonly used to enhance durability.

Protection and Drainage Layers

Membranes are often protected with:

- Geotextiles

- Drainage boards

- Screeds or insulation layers

These components prevent mechanical damage and reduce water pressure on the membrane.

Common Failure Modes

Despite robust materials, waterproofing failures still occur due to:

- Poor detailing or workmanship

- Incompatible materials

- Inadequate curing or thickness

- Mechanical damage during backfilling

- UV degradation (when exposed)

- Differential structural movement

Understanding these risks highlights the importance of system-based design rather than relying on a single product.

Maintenance and Inspection

While many membranes are designed for long service lives (20–50 years), periodic inspection is recommended, especially for:

- Roof membranes

- Exposed balconies

- Areas with high thermal or structural movement

Early detection of cracks, blisters, or seam separation can significantly reduce repair costs.

House membrane waterproofing is a technically complex but essential aspect of residential construction. The effectiveness of a waterproofing system depends not only on the membrane material itself, but also on correct design, detailing, installation, and integration with drainage and protection systems. By understanding membrane types, material properties, and application challenges, homeowners, builders, and designers can make informed decisions that ensure long-term structural integrity, occupant comfort, and durability of the building.